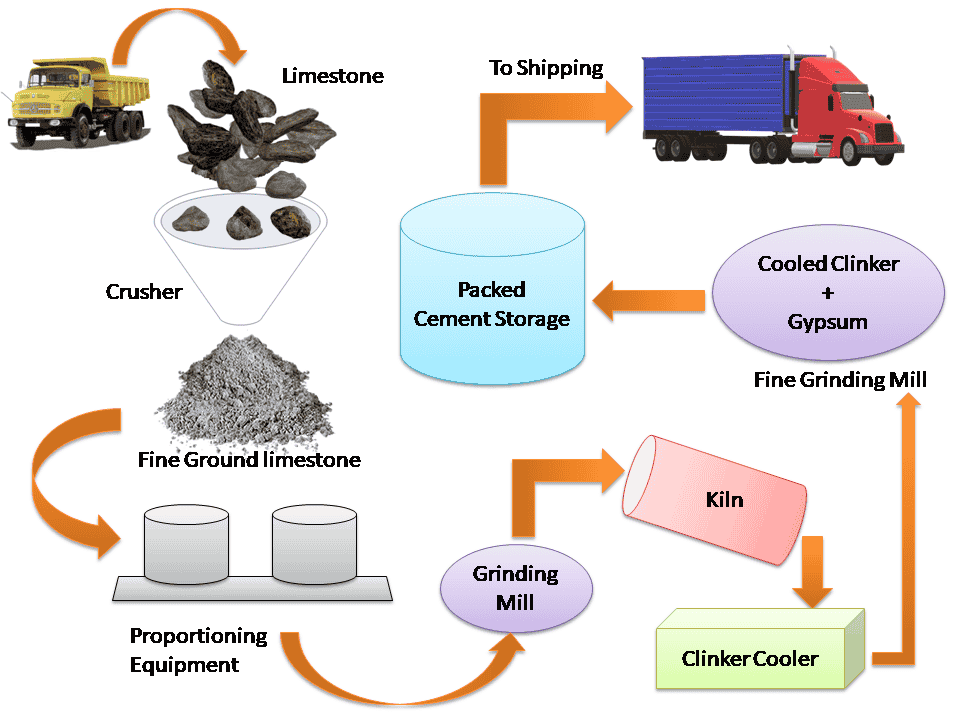

Cement manufacturing is a complex process that involves several steps. The process generally includes the following stages:

1. Raw Material Preparation

The primary raw materials used for cement production are:

- Limestone (calcium carbonate) – provides calcium.

- Clay or Shale – provides silicon, aluminum, and iron.

Other materials, such as sand or iron ore, may also be added to adjust the composition.

The raw materials are crushed and ground into a fine powder in preparation for the next stage.

2. Raw Material Mixing

The powdered raw materials are mixed in the correct proportions, either dry or with water to form a slurry (wet process). The goal is to achieve a uniform chemical composition.

3. Preheating

The raw mix is preheated in a series of cyclone chambers using hot gases from the kiln. This step helps to remove moisture and start the decomposition of raw materials.

4. Calcination

In the preheater, the material is heated to about 850°C–900°C. This decomposes limestone (calcium carbonate) into lime (calcium oxide) and releases carbon dioxide gas.

5. Clinker Formation (Kiln Phase)

The preheated mix enters a rotary kiln, a large cylindrical furnace that operates at 1,450°C–1,500°C. Here:

- Lime reacts with silica, alumina, and iron oxide to form clinker, small, dark, pebble-like nodules.

6. Cooling

The hot clinker is cooled rapidly using air to preserve its quality. Rapid cooling also prevents undesired chemical reactions.

7. Grinding

The cooled clinker is ground into a fine powder along with:

- Gypsum (added to control the setting time of cement).

- Sometimes, additional materials such as slag or fly ash are added to produce specialized cement types.

8. Packaging and Distribution

The finished cement is packed in bags or distributed in bulk to be transported to construction sites or retailers.

Types of Cement Manufacturing Processes

- Wet Process: Raw materials are mixed with water to form a slurry, making it easier to handle but energy-intensive.

- Dry Process: The raw mix is ground dry, which is more energy-efficient and commonly used today.

- Semi-Dry Process: A combination of both wet and dry methods.

This comprehensive process ensures the production of high-quality cement used in construction projects worldwide.

Leave a Reply